written by Gianluca Bibiani, the founder of the Italian journal "Strumenti e Musica"

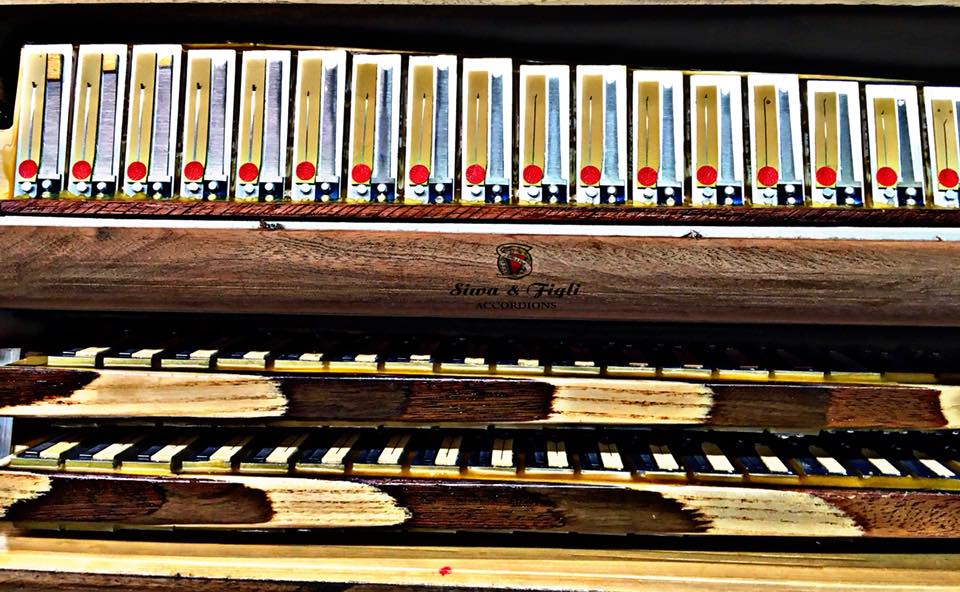

Founded in Belgrade, in 1985, by Ivan Stanojlovic and moved to Castelfidardo in 2005, the Siwa & Figli company established on the market with its excellent instruments, as a result of the experience and the craftsmanship abilities of the family, who dedicated decades to an accordion manufacturing. Dully inspired, initially with Balkan melodies, the Siwa & Figli instruments are aimed to play with any musical genre, considering a wide range of product varieties, but let’s have a detailed conversation with a daughter, Ivana Stanojlovic, a marketing manager of the company.

A family surrounded by the accordions, where this passion came from?

The accordion has always been a big passion of my family. From my childhood on, I have always seen the members of my family playing and building this lovely instrument. Starting from my grandfather (from my mother’s side) who built the keyboards for the accordions and it has been him in person, who started a craftmanship and a professional education of my father, who, at that time, used to be an accordionist and he, practically as a child, developed this huge passion toward the accordion. So one day, my father took his accordion for a repair at my Grandfa’s lab … and not only, he felt in love with my mother, the eldest daughter of my Grandfather, but this is other story. Let’s focus on what we were talking about. I grew up in my father’s factory, who initially has the headquarters and the production in Belgrade under the brand SIWA. Then we moved in Castelfidardo, in 2005 and changed the name into Siwa & Figli. As a child, what I see all around me were only accordions. I, also, played the accordion, as a child, but after years I stopped as I didn’t’ have time to continue and I dedicated myself to manage our family’s company.

Your slogan is “The accordion building process is based on the standards and the technics used in Castelfidardo in the ’60 and ‘70’s. What does it mean?

We fully believe that the “real accordion” made by hand, needs to follow the methods of the construction used in the 60’ and the 70’s, the gold epoque of Castelfidardo, where every accordions was handcrafted and every detail regarding the quality was taken into the consideration. There were many qualified people that did this work by hand and the companies did not focus a lot on the costs, but on the quality and on the value of “made in Italy”. The accordion market is full and it is difficult to find today the instrument that is manufactured according to the highest quality. The accordion lost its value today. We, all together, need to try to keep the quality “made by hand”, but we also need to keep the price of the accordion, giving the value to the accordion which it deserves.

So, from your point of view, the industrial innovation does not take to any benefit. A trained hand is better than any other machine, even if it is technologically advanced?

I would like to ask you something: why isn’t there, today, such accordion, with the same quality as it used to be found in the ’60 and ‘70’s.? At that time, the quality standard of a certain level was normal to find anywhere in Castelfidardo. I am not saying that the innovation does to take to any benefit, on the contrary. Our company grows and make experiments every day, proposing new things and trying to improve, but we need to remember what Castelfidardo was once and what is now. We try to offer to the customers the sound quality and to reproduce what the artisans used to do in the past.

We strongly believe in the Siwa & Figli accordions, above all, we love this instrument and I underline that our company is based on the value of our family. In fact, all the members of our family give their support to the company growth. A small company, that, thanks to the passion and love for this work, succeeded in bringing these valued into the family.

What is the difference between an accordion built in the past and one of the recent manufacturing?

What is the difference between an accordion built in the past and one of the recent manufacturing?

A great question. I believe that the selection of the material is very important, as well as handmade working, but above all, the technical knowledge of the instrument, from a to z, is a must. My father, who is the owner of the company, Ivan Stanojlovic, has a technical knowledge which goes to 360 degrees and he passed all his life with many sacrifices to research, experiment and create an instrument suitable to the Balkan market, which we mainly work with, and in fact this instrument turned out to be appreciated whole over the world. Today, we can say that we succeeded in satisfying this market piece. Other fundamental issue is that the accordion cannot get out of the factory till the result does not satisfy ourselves, till we are not proud of what we created. At least this is the principle I always applied and followed in my work. The client is demanding today and he cannot be treated with the inferiority. He needs to be listened and understood.

Is there a secret that characterize your instruments, the “peak” model? In case, can you describe it?

We have a lot of models, but also new ideas. At the moment we are engaged in making a new website, which will be shortly online and you will see the new, but for now, I prefer to keep it reserved. I take this occasion to thank to the person, who is working with me on this project and is putting here the same passion as me.

What is the difference between the instrument aimed to the Balkan countries and the one for Italian market? In the folk music field.

The accordion made for Balkan needs to “play”. Maybe this consideration could appear obvious, but believe me, it is not like that. Our clients look for the sound of quality, and as you know Serbia and Balkan countries venerate the accordion a lot and are looking for the absolute quality.

One of your points of force is the keyboard that is built for “the fast performances”. The additional value is in the wood type, in the manufacturing process or?

It is all in the hidden secrets. The next question?

How do you get the typical Balkan sound?

The “good ear” is required as well as a lot of dedication and the strength to obtain a valid product, a product that we personally love. Many times a client ask me “why should I buy Siwa & Figli accordions?”. I simply answer “You do not have to. Just play it you will tell me why” Most of the times the things follow their own way. The customer is not stupid, he knows and distinguish very well what is the quality and what it is not.

The result of a good musical performance is based on two components, the mechanical (instrument) and the artistic one (artist). Is there any musicians from yours that enhance the sound of Siwa accordions?

We have many artists, but I prefer calling them “friends” as with them we establish familiarity relationship and mutual respect. We have Edo Krilic, famous all over the world, Strahil Vankov, Dallas Vietty, Giacomo Tosti, Jordan Djevic, Stanislav Angelov, Ibro Bublin and many others.

What will be the future of Castelfidardo and in general for the accordion?

The future of Castelfidardo? Who knows… I believe that there is a lot to be done in order to protect the real made in Italy or, in other words, the artisan quality of the accordion. The rules needs to be created and the ways to protect the true quality and unfortunately this is missing now. The things needs to initiated from the outside, from the people that have the power to do it. We can only try to manufacture excellent accordions, then the rest, hopefully, will come.